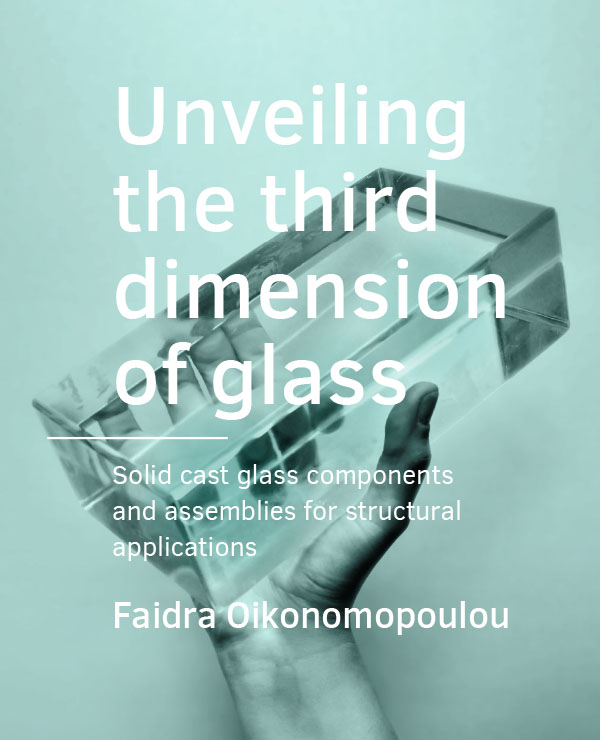

Overview of realized examples in architecture using structural cast glass blocks

DOI:

https://doi.org/10.7480/abe.2019.9.4089Abstract

In view of the meticulous and lengthy cooling process discussed in the previous chapters, in architectural applications solid cast glass components have been commercialized up to the size range of standard masonry bricks. Owing to their large cross-sectional area, solid glass bricks are promising structural components that can fully exploit glass’s compressive strength. By forming repetitive components, self-supporting, 3-dimensional all-glass structures of undisturbed transparency can be achieved. Nonetheless, at present, little and rather sporadic exploration has been made in the use of casting as a manufacturing method for structural glass in architecture. To a degree, this is attributed to the existence of only a few realized examples of self-supporting structures made of solid cast glass elements. The, so far, limited demand has in turn led to the absence of a standardized manufacturing process, to a lack of consistent engineering data and to a general unawareness of the potential of cast glass in structural applications in architecture. Currently, including the contribution of this dissertation, there are 3 structural systems employed for creating self-supporting structures out of cast glass components: (a) with a metal substructure, (b) adhesively bonded blocks, (c) interlocking glass blocks. The former two have been applied in real structures, whereas interlocking glass blocks are for the first time introduced as a building system through this dissertation. In this chapter, the 3 concepts are briefly presented, analyzed and evaluated in terms of manufacturing, structural system, level of transparency, ease of assembly and disassembly.